There is a mobilization going on in Santa Cruz County. And it stems from one simple concept: “Everyone in the nation needs to be in a mask.”

The assertion comes from Catherine S. Forest, MD, who is working with Jordan Layman of Idea Fab Labs in Santa Cruz on a fast-moving community effort to create face masks and other personal protective equipment (PPE), not just for health care professionals, but for anyone who has to go out in public.

The effort presents a vivid illustration of the power of a local community to reach a goal under the deadline of a looming crisis. Funded by donations—many of which have come from Encompass Community Services, on whose board Forest sits—the decentralized push to create protective masks on a local level is attempting to draw in and protect as many people as possible.

Idea Fab Labs, in the former Wrigley Building on the Westside of Santa Cruz, is in the business of making things. In normal times, it offers a variety of high-tech tools and software to its members—from 3-D printers to laser cutters—for small-scale manufacturing. The lab is now the epicenter for the rapid design, manufacture, and distribution of face masks and other equipment to stop the spread of the COVID-19 virus.

“We’re basically here all day, eight to 12 hours a day,” says Layman, co-founder of the company. Layman, working closely with Forest on design specifications, is putting together simple kits to make the face masks, which are then sent out to a battalion of community volunteers with sewing machines. On top of that, Layman and Forest are encouraging a DIY push by offering up instructions on how to make a mask from common material (mostly cotton). Those instructions, information on donating money or skills to the effort, requests to receive equipment, and other information on what’s happening in Santa Cruz and Monterey counties can be found on a website called Project PPE for Central Coast, at ppe4cc.org.

Originally, the Centers for Disease Control and Prevention discouraged asymptomatic and healthy people from wearing masks. “They didn’t want people to buy up all the surgical masks and take them away from health workers,” Layman says. “We’re now basically ahead of the curve on that, saying regular people should be wearing masks if they’re going out in public.” On Friday, April 3, the CDC revised their recommendation to suggest that everyone use a cloth face covering in public.

Layman and Forest began planning the manufacturing of masks several weeks ago in the early stages of the crisis. “Jordan and I started talking together,” says Forest, “and looking at what we could do, the materials that were readily available, and looking at designs that were using the best practices with the science.”

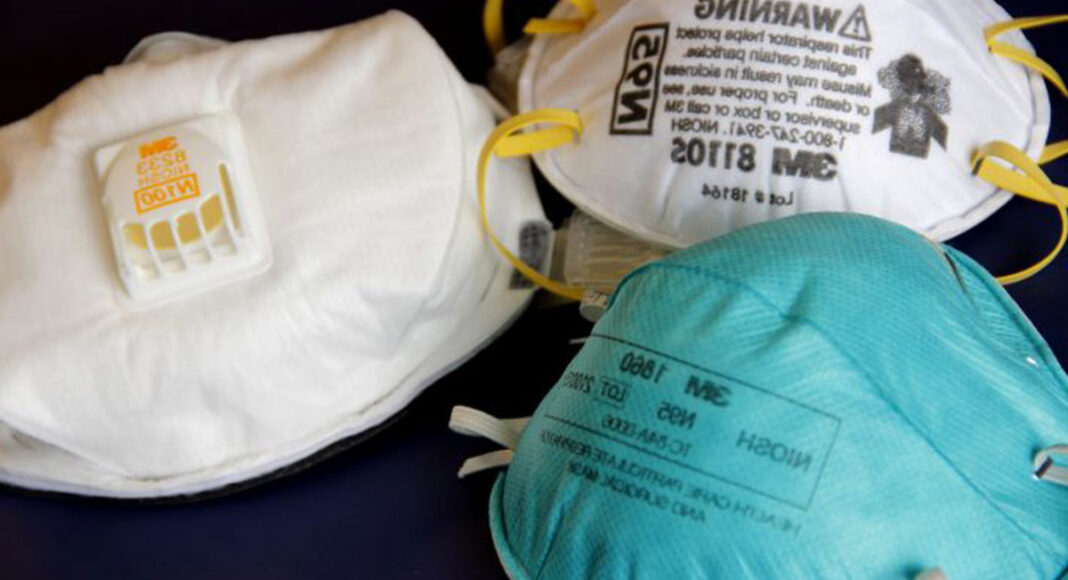

The design of the masks are based on safety elements of N95 masks, the industry standard for high-risk work, which have been in short supply in recent weeks. All certified N95 and surgical masks, Forest says, should be in the hands of medical and health-care workers. The Project PPE masks are intended for use in situations where the CDC is now suggesting the use of cloth masks.

“It’s got a nasal bridge,” she says, “form-fitting across the cheeks and chin, alternating layers of grain-cut and bias-cut fabric, an interstitial pocket for filtration, a stable banding across the back, preferably elastic so people can move in them.”

In a matter of a couple of weeks, Layman and Forest have revised their original design twice and are now working on the third iteration of the mask.

“Hopefully, we’ll be able to keep people who need a N95 mask in an N95 mask,” says Forest, whose husband is local epidemiologist Will Forest. “But now, we have farm workers piling into buses with no protection. Grocery workers, delivery people, all kinds of people who could use a better mask.”

Project PPE is not only looking to mitigate the health consequences of COVID-19, but it’s also trying to make a dent in the ongoing economic disaster as well. Encompass, for example, has led efforts in local fundraising to allow Layman and Forest to pay the seamworkers putting the masks together from their kits at home. The rate is about $3 per mask, each of which takes about 10 to 15 minutes to produce.

Layman says finding people to produce the masks while sheltering at home has not been difficult. “Some people are saying, ‘Just tell me what to do. I lost my job, so I can do this all day.’ And other people are saying, ‘My financial situation is OK right now. I don’t need to get paid. I’ll donate my time,’” he explains.

Like most other small businesses, Idea Fab Labs itself is facing an economic reckoning. “At our facility, everything is in question now as well,” Layman says. “I sort of think, in a couple of months, I’ll probably see half my membership disappear. If our members can’t even come here, why would they pay for a membership? So, we also need to find a way to change our business model.”

Layman suggests that Project PPE could probably produce between 1,500 and 2,500 masks a week at peak efficiency. But he and his partners are also working on the design and manufacture of other protective equipment, including face shields.

“Because people have 3D printers that are just going to sit idle otherwise, they want to do something,” Layman says. He’s also working on a testing interface booth to allow health care professionals the maximum protection in drive-thru testing facilities. “It’s a polycarbonate structure,” he says, of the design in progress. “It’s basically a face shield for your whole body, with these sandblaster-style gloves you can use to administer the swabs for the patient in their car.”

Idea Fab Labs and Encompass have recruited both the Santa Cruz County Medical Society and the Monterey County Medical Society in the project, in hopes of upscaling it to cover the Central Coast region.

Forest, a family physician, says she is driven to take action at a pace that would be effective in limiting the spread of the virus: “I say let’s do our damn best with the science, and we’ll revise as we go along.”

To donate money, volunteer in the manufacturing or distribution of equipment, download instructions on making masks at home, request masks or other materials, or to learn more about Project PPE, go to ppe4cc.org.

Coronavirus Coverage

For continuing in-depth coverage of the new coronavirus and its effects locally, visit goodtimes.sc/category/santa-cruz-news/coronavirus.

To learn about action you can take now, whether you’re seeking assistance or want to find ways of supporting the community, visit goodtimes.sc/santa-cruz-coronavirus-resources.

Update April 3, 7:20pm: This is story was updated to clarify how Forest says Project PPE’s masks should be used.

Good article with one glaring exception. Nowhere is it stated where the public might buy these masks. Without that the article is kind of useless except as attempting to raise funds. Offering them for sale to general public would help with their finances I’m sure. (by the way, GT “captcha” is screwed up, won’t accept correct answer)

https://iflmasks.com/?ac=santacruz

You can buy them here 🙂